Nec requirements for making cable terminations and splices – The National Electrical Code (NEC) sets forth stringent requirements for making cable terminations and splices to ensure the safety and reliability of electrical installations. Understanding these requirements is crucial for electricians and anyone working with electrical systems.

This comprehensive guide delves into the NEC’s stipulations for cable terminations and splices, covering their purpose, types, proper techniques, safety considerations, necessary tools and equipment, and testing and inspection procedures.

NEC Requirements for Cable Terminations

NEC (National Electrical Code) establishes comprehensive requirements for electrical installations, including the proper termination of cables. These requirements aim to ensure the safety and reliability of electrical systems by specifying the techniques and materials necessary for secure and effective cable terminations.

Proper cable terminations are crucial to prevent electrical hazards such as short circuits, arcing, and overheating. NEC requirements provide guidelines for:

- Selecting the appropriate termination method based on the type of cable, voltage, and application.

- Preparing the cable ends for termination, including stripping the insulation and crimping or soldering the connectors.

- Using the correct tools and equipment for termination, such as crimpers, strippers, and torque wrenches.

- Inspecting and testing the completed terminations to ensure proper installation and functionality.

Types of Cable Terminations

NEC recognizes various types of cable terminations, each suitable for specific applications:

- Crimp Terminations:Involve using a crimping tool to compress a metal connector onto the cable end, creating a secure mechanical connection.

- Solder Terminations:Utilize solder to create a permanent electrical and mechanical bond between the cable end and the connector.

- Screw Terminations:Employ screws to fasten the cable end to a terminal block or other electrical device.

- Push-In Terminations:Feature spring-loaded connectors that allow for quick and easy insertion of the cable end without the need for tools.

NEC Requirements for Cable Splices, Nec requirements for making cable terminations and splices

NEC also establishes requirements for cable splices, which involve connecting two or more cables together. Proper splicing techniques are essential to maintain the integrity and functionality of electrical systems.

NEC guidelines for cable splices include:

- Selecting the appropriate splicing method based on the type of cable, voltage, and environmental conditions.

- Preparing the cable ends for splicing, including stripping the insulation and twisting or soldering the conductors together.

- Using the correct materials and techniques for splicing, such as heat shrink tubing, solder, and electrical tape.

- Inspecting and testing the completed splices to ensure proper installation and functionality.

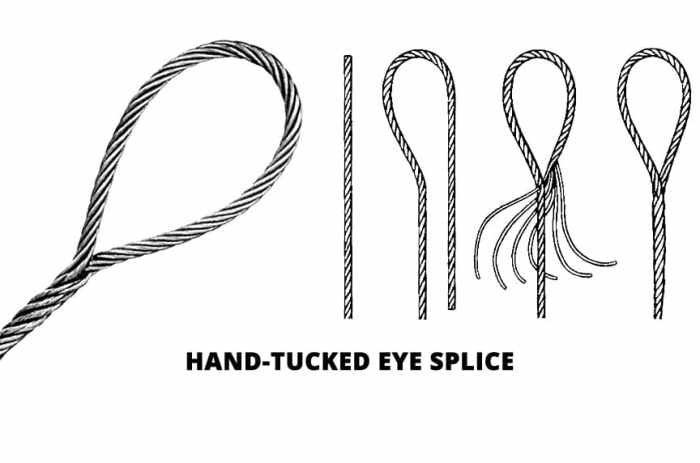

Types of Cable Splices

NEC recognizes various types of cable splices, each suitable for specific applications:

- Crimp Splices:Involve using a crimping tool to compress a metal connector onto the twisted conductors, creating a secure mechanical connection.

- Solder Splices:Utilize solder to create a permanent electrical and mechanical bond between the twisted conductors.

- Heat Shrink Splices:Employ heat shrink tubing to insulate and protect the spliced conductors.

- Mechanical Splices:Use a mechanical device to hold the spliced conductors together, such as a wire nut or Scotchlok connector.

Question Bank: Nec Requirements For Making Cable Terminations And Splices

What is the purpose of the NEC requirements for cable terminations and splices?

The NEC requirements aim to ensure the proper installation and maintenance of electrical connections, preventing electrical hazards such as fires, shocks, and equipment damage.

What are the different types of cable terminations?

Common cable terminations include crimping, soldering, and insulation displacement connectors, each suited for specific cable types and applications.

How can I ensure proper cable splicing techniques?

Proper splicing involves using compatible splicing connectors, stripping the cable insulation to the correct length, and securely connecting the conductors, followed by insulation and sealing to prevent moisture ingress.