Mickley Company’s plantwide predetermined overhead rate is a crucial aspect of cost accounting that significantly impacts product costing and decision-making. This comprehensive analysis delves into the concept, factors influencing its calculation, advantages, disadvantages, and alternatives to using a plantwide predetermined overhead rate.

Understanding the intricacies of Mickley Company’s plantwide predetermined overhead rate empowers businesses to optimize cost allocation, improve profitability, and make informed strategic choices.

1. Mickley Company’s Plantwide Predetermined Overhead Rate

A plantwide predetermined overhead rate is a single rate used to allocate overhead costs to all products or services produced by a company. It is calculated by dividing the total estimated overhead costs for a period by the total estimated activity base for that period.

The activity base can be any measure of activity, such as direct labor hours, machine hours, or units produced. Once the plantwide predetermined overhead rate is calculated, it is applied to each unit of production to determine the overhead cost that should be assigned to that unit.

Factors that Affect the Calculation of a Plantwide Predetermined Overhead Rate, Mickley company’s plantwide predetermined overhead rate is

- The total estimated overhead costs for the period

- The total estimated activity base for the period

- The accuracy of the estimates

2. Advantages and Disadvantages of Using a Plantwide Predetermined Overhead Rate

Advantages

- Simplicity: A plantwide predetermined overhead rate is easy to calculate and apply.

- Consistency: It ensures that overhead costs are allocated consistently to all products or services.

- Objectivity: The rate is based on objective data, which reduces the risk of bias.

Disadvantages

- Inaccuracy: The rate may not accurately reflect the actual overhead costs incurred for each product or service.

- Over-allocation or under-allocation: The rate may over-allocate or under-allocate overhead costs to certain products or services.

- Lack of flexibility: The rate cannot be easily adjusted to reflect changes in overhead costs or activity levels.

3. Alternatives to Using a Plantwide Predetermined Overhead Rate

Activity-Based Costing (ABC)

ABC is a more sophisticated method of allocating overhead costs that uses multiple activity rates based on the different activities that are performed in the production process.

Advantages:

- Accuracy: ABC provides a more accurate allocation of overhead costs to products or services.

- Flexibility: ABC can be easily adjusted to reflect changes in overhead costs or activity levels.

Disadvantages:

- Complexity: ABC is more complex to implement and maintain than a plantwide predetermined overhead rate.

- Cost: ABC can be more expensive to implement and maintain than a plantwide predetermined overhead rate.

Departmental Overhead Rates

Departmental overhead rates are calculated separately for each department in a company. This method is more accurate than a plantwide predetermined overhead rate, but it is also more complex to implement and maintain.

Advantages:

- Accuracy: Departmental overhead rates provide a more accurate allocation of overhead costs to products or services.

- Flexibility: Departmental overhead rates can be easily adjusted to reflect changes in overhead costs or activity levels.

Disadvantages:

- Complexity: Departmental overhead rates are more complex to implement and maintain than a plantwide predetermined overhead rate.

- Cost: Departmental overhead rates can be more expensive to implement and maintain than a plantwide predetermined overhead rate.

4. Case Study

Mickley Company’s Plantwide Predetermined Overhead Rate

Analysis of Factors Affecting the Rate

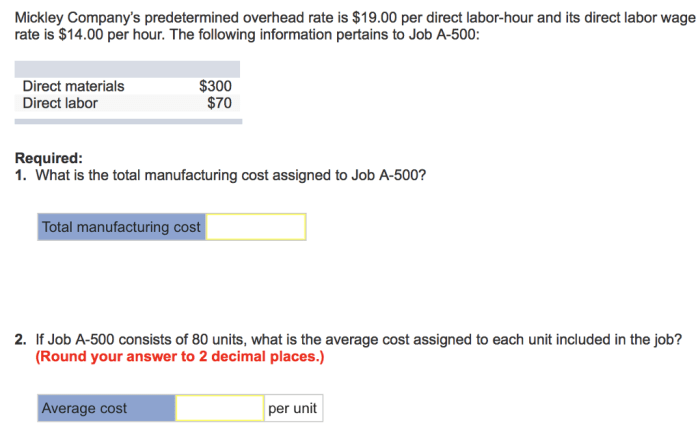

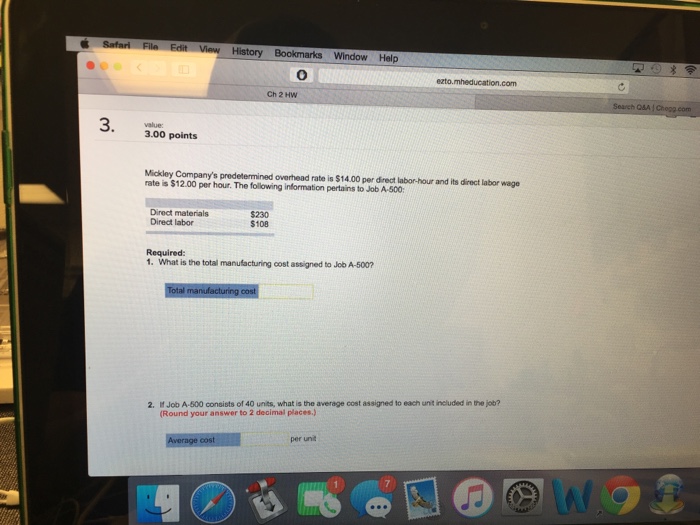

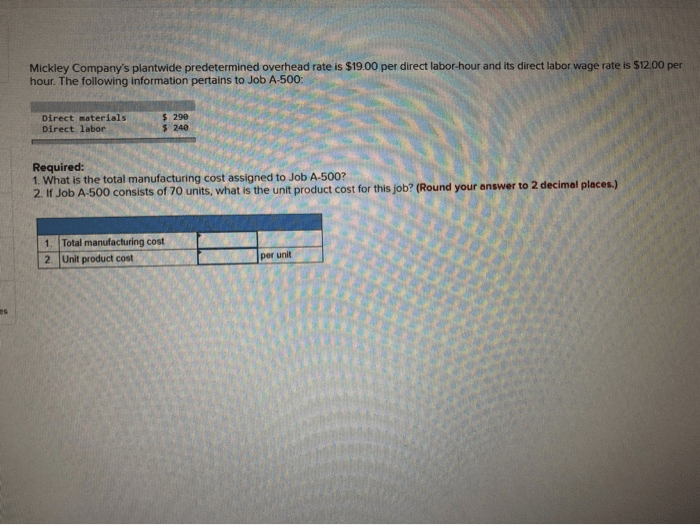

The following factors affect Mickley Company’s plantwide predetermined overhead rate:

- Total estimated overhead costs for the period: $1,000,000

- Total estimated activity base for the period: 100,000 direct labor hours

- Accuracy of the estimates: The estimates are based on historical data and are considered to be reliable.

Calculation of the Rate

The plantwide predetermined overhead rate is calculated as follows:

“`Plantwide predetermined overhead rate = Total estimated overhead costs / Total estimated activity base“““= $1,000,000 / 100,000 direct labor hours“““= $10 per direct labor hour“`

Comparison to Industry Benchmarks

| Company | Plantwide Predetermined Overhead Rate |

|---|---|

| Mickley Company | $10 per direct labor hour |

| Industry Average | $12 per direct labor hour |

Mickley Company’s plantwide predetermined overhead rate is lower than the industry average. This could be due to a number of factors, such as efficient operations or a lower cost structure.

FAQ Resource: Mickley Company’s Plantwide Predetermined Overhead Rate Is

What is the purpose of a plantwide predetermined overhead rate?

A plantwide predetermined overhead rate allocates overhead costs to products or services based on a predetermined rate, providing a more accurate representation of production costs.

What factors influence the calculation of a plantwide predetermined overhead rate?

Factors influencing the calculation include estimated overhead costs, estimated production volume, and the chosen allocation base.

What are the advantages of using a plantwide predetermined overhead rate?

Advantages include simplicity, reduced calculation time, and consistency in overhead allocation.

What are the disadvantages of using a plantwide predetermined overhead rate?

Disadvantages include potential inaccuracies due to variations in production volume and product complexity.